Our capabilities & services

Hinz Company

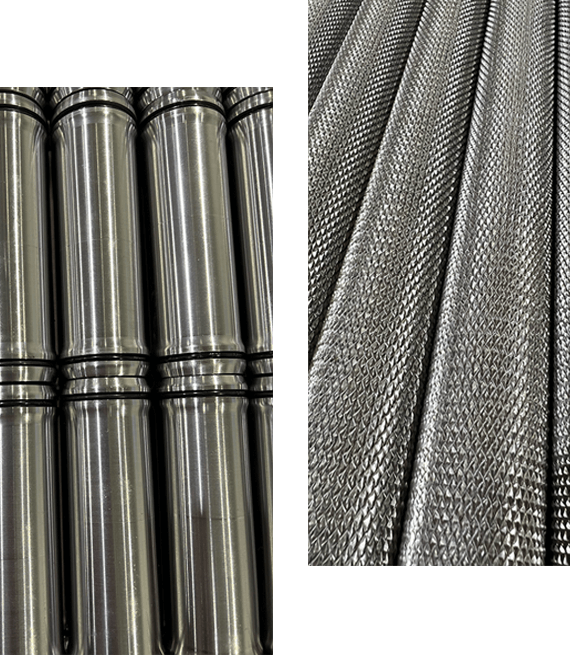

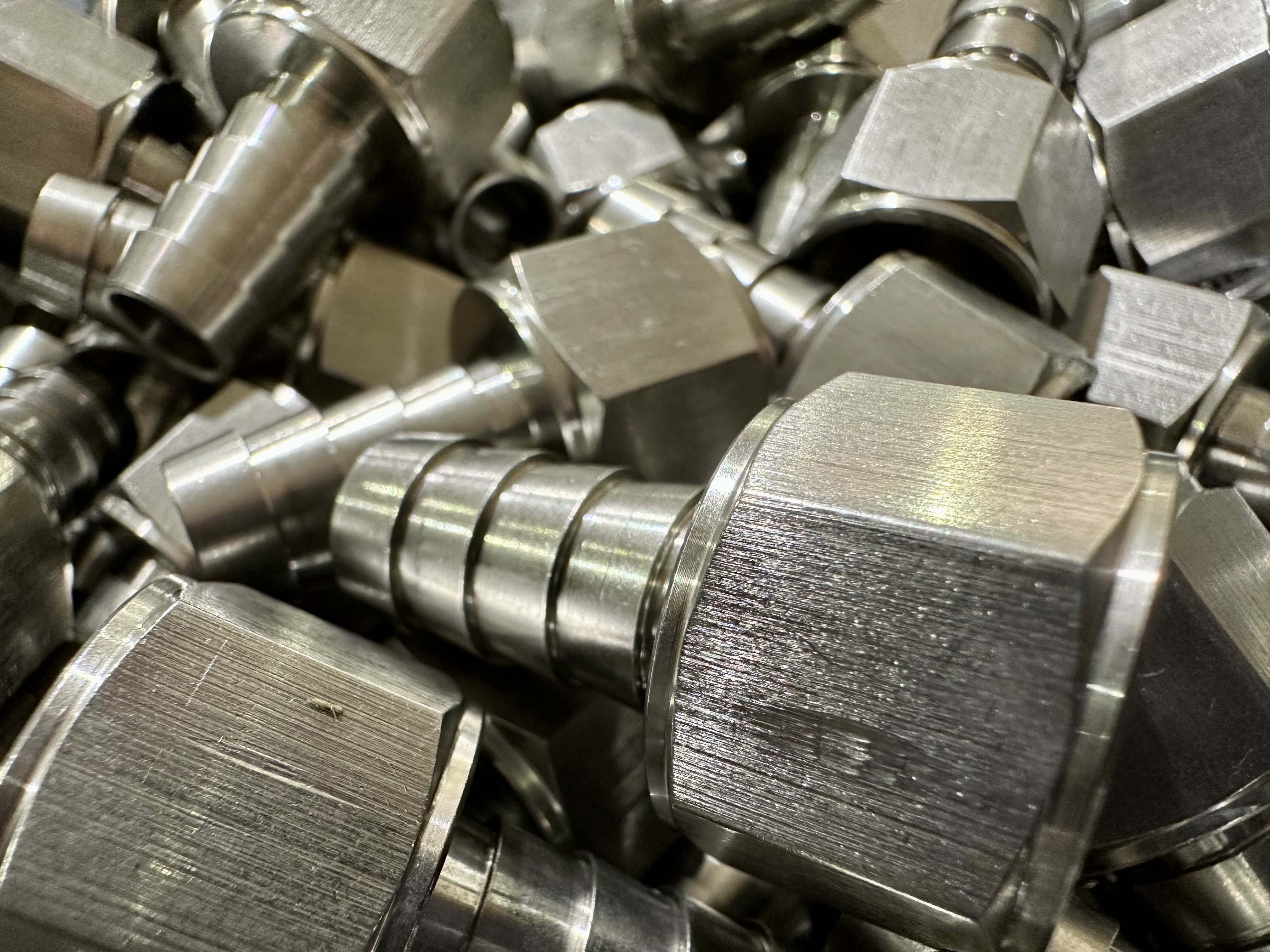

Hinz was founded on the demand for high quality welding tips, nozzles and related parts, including CCZ long-life welding tips. It is based on that history that we have become the most competitive source for high precision small and complex parts.

Our experienced staff all work with the same goal in mind: to provide quality custom machined parts that exceed our customers' expectations, on schedule and at competitive costs. Our people make the difference, applying their experience to reduce the machining steps and reduce waste. We can then pass the added value on to our customers with lower costs. Find out how we can help you with your component machining. Contact Hinz Company for more information, or to submit drawings for a no-obligation quote.

About The Hinz Company

Since 1958 The Hinz Company has focused on providing our customers the finest quality machined parts, through innovative manufacturing processes and responsive service, at very competitive costs. We've built long-term relationships with many of our customers by providing the solutions that help them build better products.

Our experienced staff all work with the same goal in mind: to provide quality components that exceed our customers' expectations, on schedule and at competitive costs. Our people make the difference, applying their experience to reduce the machining steps and reduce waste. We can then pass the added value on to our customers with lower costs. Find out how we can help you with your component machining. Contact The Hinz Company for more information, or to submit drawings for a no-obligation quote.

Hinz was founded on the demand for high quality welding tips, nozzles and related parts, including CCZ long-life welding tips. It is based on that history that we have become the most competitive source for high precision small and complex parts.

- Experienced staff

- Finest quality

- Quality components

- Competitive source

- High precision

- Small & complex parts

Latest news

Custom Machined Parts

By seamlessly integrating advanced CNC machining technologies, The Hinz Company positions itself at the forefront precision engineering of custom machines parts. Their dedication to innovation is reflected in their state-of-the-art manufacturing processes, which enable the production of intricate custom machined parts with exceptional accuracy and efficiency. The company's responsive service is a cornerstone of their operations, ensuring that clients' unique specifications and requirements are not only met but exceeded. This commitment to tailored solutions has solidified enduring relationships with clients, as The Hinz Company becomes a trusted partner in the realization of superior products. Moreover, their competitive cost structure underscores their commitment to delivering value, making them an industry leader in the realm of custom machined parts.

Looking for High Volume Swiss CNC Parts?

Hinz Company specializes in the production of high-volume Swiss CNC machined parts, leveraging advanced Swiss machining technology for precision manufacturing. Their expertise caters to diverse industries, including medical, electronics, aerospace, automotive, and watchmaking. Hinz Company excels in crafting intricate components like surgical instruments, electronic connectors, aerospace hardware, automotive parts, and precision watch components. With a focus on efficiency, their employment of simultaneous machining on CNC lathes ensures faster production times, meeting the demands of mass production. Hinz Company's commitment to versatility is evident in their ability to work with various materials, underscoring their flexibility in addressing specific manufacturing needs and consistently delivering high-precision CNC parts.