| Processes (General Capabilities) |

Boring Milling |

| Processes (Special Capabilities) |

Broaching Slotting |

| Processes (Threading) |

External Thread Cutting Thread Grinding |

| Part Length |

Min Max |

| Outer Diameter |

Min Max |

| Tolerance (±/-) |

0.0005 in Tight Tolerance |

| Production Volume |

Min Max |

| Industry Focus |

Aerospace Hydraulic |

| Intended Application |

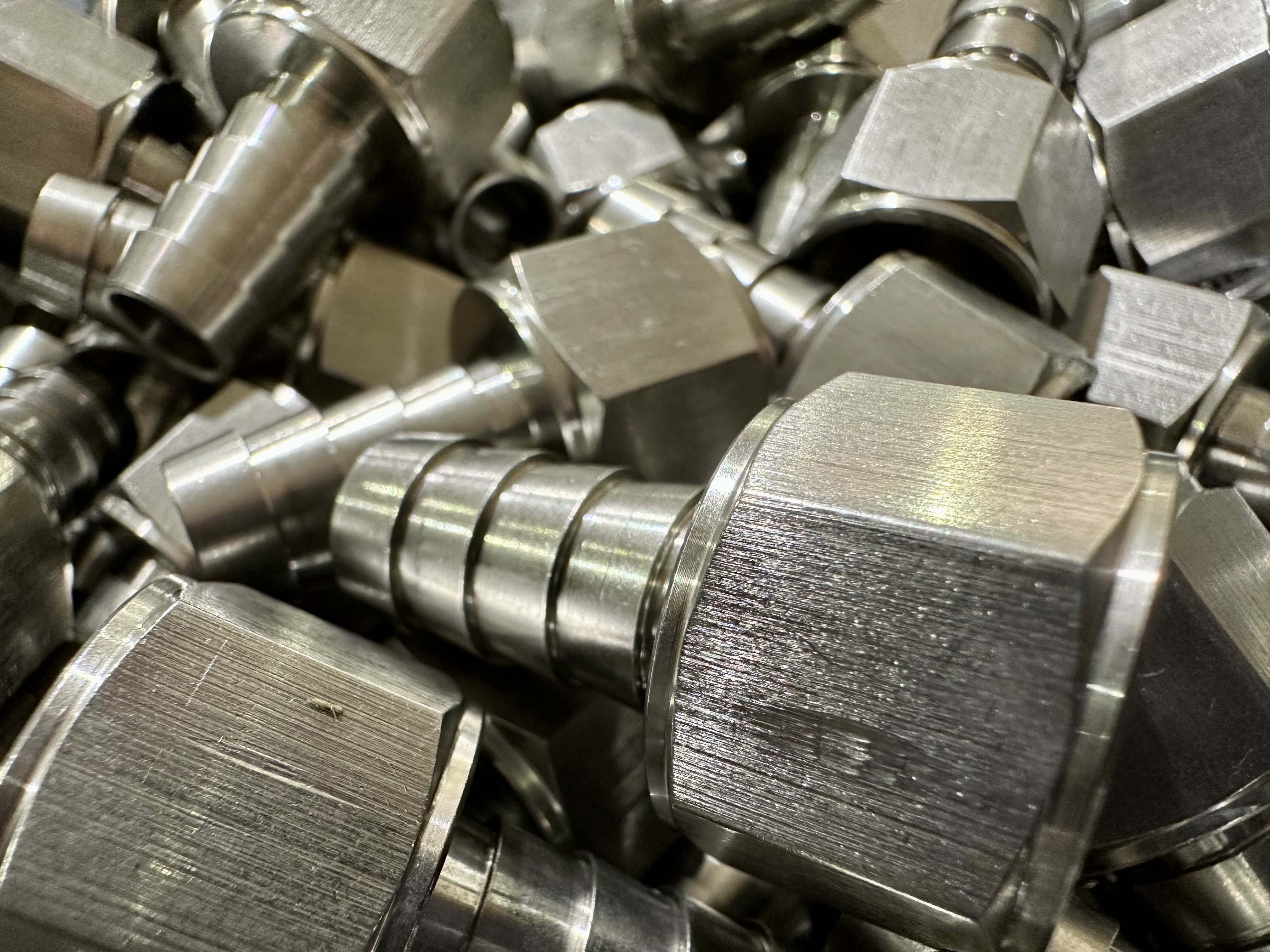

Connectors Poppets |

| Lead Times Available |

Quoted on job by job basis Rush Services Available |

| Industry Standards |

International Organization for Standardization ISO-9001 |

| Additional Capabilities |

CAD Design Services CAM Programming Services |

| Equipment Capabilities |

8-Axis Machining Capabilities CNC Control Capabilities |

| Efficiency |

Six Sigma Compliant Lights Out Manufacturing |

| File Formats | AutoCAD (DWG,DWZ) |

| Part Length |

Min Max |

| Outer Diameter |

Min Max |

| Tolerance (±/-) |

0.0005 in Tight Tolerance |

| Production Volume |

Min Max |

| Industry Focus |

Aerospace Hydraulic |

| Intended Application |

Connectors Poppets |

| Lead Times Available |

Quoted on job by job basis Rush Services Available |

| Industry Standards |

International Organization for Standardization ISO-9001 |

| Additional Capabilities |

CAD Design Services CAM Programming Services |

| Equipment Capabilities |

8-Axis Machining Capabilities CNC Control Capabilities |

| Materials (Metals) |

Alloy Steels Copper |

| Materials (Plastic Polymers) |

ABS (Acrylonitrile Butadiene Styrene) Polyetherimide |

| Efficiency |

Six Sigma Compliant Lights Out Manufacturing |

| File Formats | AutoCAD (DWG,DWZ) |

Materials to Support Our Multi Axis Machining Capabilities

Metals: Alloy Steels, Aluminum, Beryllium, Brass, Bronze Alloys, Carbon Steel, Copper, Molybdenum, Nickel, Palladium, Stainless Steel, Steel, Titanium.

Materials (Plastic Polymers): ABS (Acrylonitrile Butadiene Styrene), Acetal, Acrylic, Fiberglass Reinforced Plastics, Nylon, Phenolic, Polyamide-Imide, Polycarbonate, Polyetheretherketone (PEEK), Polyetherimide, Polyethylene, Polyphenylene Sulfide, Polypropylene, Polystyrene, PolyTetraFluoroEthylene (PTFE), Polyvinyl Chloride (PVC), Polyvinylidene Fluoride (PVDF), Teflon ®.

-

Custom CNC Turning of Plug Assembly for the Hydraulic Industry

The Hinz Company is well known for providing both reliable and cost-effective service in the area of machining and component assembly. Hinz was recently retained by the l...

-

Custom Multi-Axis Machining of a Mild Steel Push Rod for the Motorcycle Industry

Known for producing cost-effective machining and component assembly solutions, The Hinz Company was contracted by a client from the motorcycle industry t...

-

Custom CNC Swiss Machining of a Brass Multipositional Valve for a Power Tool Application

Knowing our reputation for providing streamlined, cost-effective quality service in the area of machining and component assembly, The Hinz Company was contracted by a cli...

-

CNC Multi-Axis Turning of a Stainless Steel Hold-Down Knob for the Aerospace Industry

Contracted by an aerospace industry leader, The Hinz Company constructed a multi-axis turned hold-down knob used for commerical airline applications. Produced from s...

Whether you need precise components for aircraft engines, avionics systems, or other critical aerospace applications, The Hinz Company is your trusted source. Our commitment to excellence in CNC Multi Axis Swiss Turning services, combined with our industry-specific knowledge, positions us as a reliable partner for all your aerospace machining needs. Experience the precision and quality that set us apart in the Aerospace industry with The Hinz Company.

When you require precise components for agricultural machinery, irrigation systems, or other critical applications in the agriculture industry, The Hinz Company is your trusted source. Our dedication to excellence in CNC Multi Axis Swiss Turning services, coupled with our industry-specific expertise, makes us a reliable partner for all your agricultural machining requirements. Discover the accuracy and quality that distinguish us in the Agriculture sector with The Hinz Company.

When it comes to precise components for automotive engines, electronic systems, or other critical automotive applications, look no further than The Hinz Company. We excel in CNC Multi Axis Swiss Turning services and possess specialized knowledge of the automotive industry, making us the dependable partner you need for all your machining requirements. Discover unparalleled precision and quality that sets us apart in the Automotive sector with The Hinz Company.

When it comes to precise components for hydraulic systems, whether it's for aircraft engines, avionics, or other critical applications, The Hinz Company is your trusted source. Our dedication to excellence in CNC Multi Axis Swiss Turning services, along with our specialized knowledge in hydraulics, makes us the reliable partner you need for all your hydraulic machining needs. Experience the unmatched precision and quality that sets us apart in the Hydraulic industry with The Hinz Company.

When it comes to precise components for medical equipment, medical devices, or other critical medical applications, The Hinz Company is your trusted source. Our dedication to excellence in CNC Multi Axis Swiss Turning services, along with our industry-specific knowledge in the medical field, makes us a reliable partner for all your medical machining needs. Experience the precision and quality that set us apart in the Medical industry with The Hinz Company.

Alloy steels, a category of steel incorporating diverse alloying elements alongside carbon, aim to augment specific properties. Elements like chromium, nickel, and manganese are introduced to enhance strength, hardness, toughness, and other attributes. These steels are classified based on composition, encompassing low-alloy, medium-alloy, high-alloy, tool steels, and HSLA steels. In CNC (Computer Numerical Control) machining, alloy steels play a vital role due to their tailored properties.

CNC machining involves using computer-controlled machines to precisely shape and cut materials. Alloy steels are preferred in CNC machining for their improved mechanical characteristics, making them suitable for various applications. The specific alloying elements present in these steels can enhance machinability, wear resistance, and overall performance during the CNC machining process.

In industries like automotive and aerospace, where stringent performance requirements are essential, CNC machining with alloy steels becomes crucial. The choice of alloying elements is carefully made to align with the desired properties of the final CNC-machined product. Whether it's crafting intricate components or producing durable parts with specific mechanical attributes, alloy steels contribute significantly to the versatility and effectiveness of CNC machining in diverse manufacturing sectors.

Aluminum, with the chemical symbol Al and atomic number 13, is a lightweight and corrosion-resistant metal abundant in the Earth's crust. Extracted mainly from bauxite, it possesses key qualities such as ductility, conductivity, and high reflectivity. This versatile metal finds extensive use in construction, transportation, and packaging due to its low density, making it valuable where weight is a critical factor. Moreover, aluminum's recyclability and low melting point contribute to its sustainability.

In CNC (Computer Numerical Control) machining, aluminum is a preferred material for a variety of applications. Its lightweight nature facilitates faster machining processes, reducing tool wear and extending tool life. The metal's excellent thermal conductivity allows for efficient heat dissipation during machining, preventing excessive tool temperatures. Additionally, aluminum's malleability allows for intricate designs and tight tolerances in CNC-machined components.

Common CNC-machined aluminum parts include aerospace components, automotive parts, electronic enclosures, and consumer goods. The material's favorable characteristics, such as ease of milling, turning, and drilling, make it well-suited for CNC machining operations. Overall, aluminum's properties make it an ideal choice for precision manufacturing using CNC techniques. Aluminum Machining Quotes - click here

Beryllium is a chemical element with the symbol Be and atomic number 4. It is a relatively rare and lightweight metal with excellent stiffness, thermal conductivity, and electrical conductivity. Beryllium is primarily extracted from minerals like beryl and bertrandite.

In CNC machining, beryllium is often used to produce components and parts with intricate designs and tight tolerances. It is employed in the fabrication of specialized components for aerospace, defense, and electronics industries. Examples include lightweight structural components in aerospace applications, heat sinks for electronic devices, and certain tooling components.

Beryllium is highly prized for its distinctive qualities, finding application in specific contexts that benefit from its unique characteristics:

- Lightweight and Stiffness: Beryllium's exceptional lightweight nature and high stiffness make it ideal for situations demanding a balance of strength and low weight, particularly advantageous in the aerospace and defense industries.

- Thermal Conductivity: Beryllium's excellent thermal conductivity allows efficient heat dissipation, proving valuable in applications where effective heat management is crucial, such as in certain electronic components.

- Electrical Conductivity: Serving as a good electrical conductor, beryllium is employed in applications requiring essential electrical conductivity, including connectors and specific electronic components.

- Dimensional Stability: Beryllium exhibits minimal thermal expansion, ensuring excellent dimensional stability. This property is vital in applications where precise tolerances and stability across temperature ranges are necessary.

Brass is a metal alloy primarily composed of copper and zinc. The proportion of copper to zinc can vary, leading to different types of brass with varied properties. Other elements, such as lead or tin, might be included in brass alloys to further modify their characteristics.

In CNC machining, brass is a popular material due to its favorable properties. Here's how it is commonly used:

- Precision Components: Brass is well-suited for CNC machining of precision components and parts due to its machinability and dimensional stability.

- Decorative Parts: The attractive appearance of polished brass makes it a preferred choice for manufacturing decorative components and parts.

- Electrical Connectors: Brass's good electrical conductivity makes it suitable for manufacturing electrical connectors, terminals, and other electrical components.

- Fasteners and Fittings: Brass is often used in the production of screws, nuts, bolts, and various fittings due to its corrosion resistance and ease of machining.

- Valve and Plumbing Components: Brass is commonly used in the manufacturing of valves, fittings, and plumbing components due to its corrosion resistance and durability.

CNC machining of brass involves using computer-controlled machines to precisely shape and cut the material. The machinability of brass, along with its versatility and range of favorable properties, makes it a reliable choice for various applications across industries.

Bronze is a metal alloy that primarily consists of copper, but it is alloyed with other elements, usually tin. Other elements like aluminum, silicon, phosphorus, or manganese may also be added to create specific bronze alloys with desirable properties. Bronze alloys exhibit a range of characteristics, including good corrosion resistance, high strength, and excellent wear resistance.

In CNC machining, bronze alloys are utilized for various applications due to their favorable characteristics. Here's how they are commonly used:

- Bushings and Bearings: Bronze alloys, especially phosphor bronze, are frequently employed in the CNC machining of bushings and bearings due to their excellent wear resistance and self-lubricating properties.

- Gears and Components: Bronze alloys, such as manganese bronze, are used in the machining of gears and other mechanical components where strength, durability, and corrosion resistance are crucial.

- Decorative Components: Bronze's attractive appearance, when polished, makes it suitable for CNC machining decorative components and art pieces.

- Valve Components: Certain bronze alloys are chosen for CNC machining valve components due to their corrosion resistance and durability in demanding environments.

- Marine Hardware: Aluminum bronze is often used in CNC machining marine hardware components due to its corrosion resistance, especially in saltwater environments.

The machinability of bronze alloys makes them well-suited for CNC machining processes, allowing for the production of precise and intricate components. The specific choice of bronze alloy depends on the desired properties of the final product and its intended application.

Carbon steel is a type of steel that primarily consists of iron and carbon, with the carbon content typically ranging from 0.05% to 2.0%. Carbon steel may also contain small amounts of other alloying elements such as manganese, sulfur, phosphorus, and silicon. The carbon content and the presence of other elements influence the properties of carbon steel, including its strength, hardness, and machinability.

In CNC machining, carbon steel is utilized for a variety of applications. Here's how it is commonly used:

- Structural Components: Carbon steel is frequently used in the CNC machining of structural components for buildings, bridges, and machinery due to its strength and durability.

- Shafts and Axles: The machinability and strength of carbon steel make it suitable for producing shafts, axles, and other components in machinery and automotive applications.

- Fasteners: Carbon steel is commonly used in the CNC machining of screws, bolts, and other fasteners due to its strength and ease of fabrication.

- Tooling and Dies: Carbon steel is often employed in the manufacturing of CNC machined tooling and dies, taking advantage of its hardness and wear resistance.

- Gears and Gear Components: Carbon steel gears and gear components are machined for various applications, including in machinery and automotive systems.

CNC machining of carbon steel involves using computer-controlled machines to precisely shape and cut the material. The machinability of carbon steel makes it a preferred choice for a wide range of applications where precision and strength are essential. Different grades of carbon steel may be chosen based on the specific requirements of the end product.

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with high thermal and electrical conductivity, and it exhibits excellent corrosion resistance. Copper has been used by humans for thousands of years due to its various desirable properties.

Uses of Copper in CNC Machining:

- Electrical Components: Copper is widely used in the CNC machining of electrical components such as connectors, terminals, and conductive elements due to its excellent electrical conductivity.

- Heat Sinks: The high thermal conductivity of copper makes it suitable for manufacturing heat sinks, which are used to dissipate heat from electronic devices.

- Plumbing Fittings: Copper is used in CNC machining to create plumbing fittings due to its corrosion resistance and malleability.

- Decorative Components: The attractive reddish-brown color of copper, as well as its ability to take on a patina over time, makes it popular for CNC machining decorative components and art pieces.

- Rotational Parts: Copper is used in CNC machining for parts that require high rotational speed, such as gears and bushings.

- Antimicrobial Surfaces: Copper has natural antimicrobial properties, and CNC machining is employed to create surfaces, such as doorknobs and handrails, to help reduce the spread of microbes.

Copper's properties make it a versatile material for CNC machining, and it is often chosen for applications where its conductivity, heat transfer capabilities, and corrosion resistance are crucial. The specific alloy and grade of copper may be selected based on the desired properties of the final product.

Molybdenum is a chemical element with the symbol Mo and atomic number 42. It is a silvery-white, hard, and refractory metal that has a high melting point and excellent mechanical and thermal properties. Molybdenum is commonly found in various minerals and is often alloyed with other metals to enhance their properties.

In CNC (Computer Numerical Control) machining, molybdenum is used in various applications where its unique properties are beneficial:

- Aerospace Components: Molybdenum is utilized in CNC machining for aerospace components, especially in high-temperature environments where its high melting point and strength are advantageous.

- Tooling and Dies: Molybdenum is used in the production of CNC machined tooling and dies due to its hardness and resistance to wear and deformation.

- Electrical and Electronic Components: Molybdenum is employed in CNC machining for electrical and electronic components, including contacts, because of its electrical conductivity and resistance to arc erosion.

- Heat Sinks: Molybdenum's good thermal conductivity makes it suitable for manufacturing heat sinks used in electronic devices to dissipate heat effectively.

- High-Temperature Furnace Parts: Due to its ability to withstand high temperatures, molybdenum is used in CNC machining for parts in high-temperature furnaces and industrial processes.

CNC machining of molybdenum involves using computer-controlled machines to precisely shape and cut the material. The material's unique combination of properties makes it valuable in applications where durability, high-temperature resistance, and mechanical strength are critical requirements.

Nickel is a chemical element with the symbol Ni and atomic number 28. It is a silvery-white, lustrous metal with good corrosion resistance. Nickel is known for its ability to alloy with other metals, forming a wide range of alloys with diverse properties. These nickel alloys are used in various applications due to their unique combination of characteristics.

In CNC (Computer Numerical Control) machining, nickel and nickel alloys are used for various applications where their specific properties are advantageous:

- Aerospace Components: Nickel alloys, such as Inconel and Monel, are used in CNC machining for aerospace components due to their high strength, corrosion resistance, and ability to withstand high temperatures.

- Chemical Processing Equipment: Nickel alloys are employed in the CNC machining of equipment for chemical processing industries due to their corrosion resistance in corrosive environments.

- Electronics: Nickel is used in CNC machining for electronic components, including connectors and contacts, where its conductivity and corrosion resistance are beneficial.

- Medical Devices: Nickel alloys are utilized in the CNC machining of medical devices due to their biocompatibility and corrosion resistance.

- Marine Applications: Nickel alloys find applications in CNC machining for marine components, such as valves and fasteners, where corrosion resistance in saltwater environments is crucial.

CNC machining of nickel involves using computer-controlled machines to precisely shape and cut the material. The choice of nickel or a specific nickel alloy depends on the requirements of the final product, such as strength, corrosion resistance, and thermal stability. Nickel's versatility and ability to enhance the properties of other materials make it valuable in various industries and applications.

Palladium is a chemical element with the symbol Pd and atomic number 46. It is a rare and lustrous silver-white metal that belongs to the platinum group of elements. Palladium, like other platinum group metals, has a range of unique properties that make it valuable in certain applications.

In CNC (Computer Numerical Control) machining, palladium is not commonly used as a primary material for machining due to its rarity and high cost. However, it can be used indirectly in the form of palladium-containing alloys or as a coating for specific applications. Some potential uses of palladium and its alloys in CNC machining-related processes include:

- Electronics: Palladium is used in the plating of electrical connectors and components due to its excellent conductivity and corrosion resistance.

- Catalysts: Palladium-based catalysts may be used in CNC machining for chemical processing applications, where their catalytic activity is essential.

- Jewelry: Palladium is a precious metal and is sometimes used in CNC machining for the production of high-end jewelry due to its attractive appearance and corrosion resistance.

- Medical Devices: Palladium-containing alloys may be used in CNC machining for certain medical devices where biocompatibility and corrosion resistance are critical.

Stainless steel is widely used in CNC machining for its versatile properties, including corrosion resistance, strength, and aesthetic appeal. In CNC machining, stainless steel is employed to create precision components for aerospace, automotive, medical, and food processing applications. Its durability makes it suitable for tooling, dies, and fasteners, while its aesthetic qualities are utilized in decorative and architectural elements. CNC machining of stainless steel involves using computer-controlled machines to shape the material precisely, and the specific grade chosen depends on the application's requirements, such as corrosion resistance or strength. Overall, stainless steel's adaptability and durability make it a popular material for a diverse range of CNC-machined components across various industries.

Steel, an alloy of iron and carbon with additional elements, is widely used in CNC machining for its strength, durability, and versatility. In CNC machining, steel is employed to create diverse components, including structural parts for construction and machinery, tooling and dies with high hardness, gears and transmission components for wear resistance, fasteners such as screws and bolts, automotive parts, bearings and bushings, oil and gas industry components, and various consumer goods. CNC machining of steel involves using computer-controlled machines to precisely shape and cut the material, with the choice of specific steel grades and alloys tailored to the application's requirements, considering factors like strength, hardness, machinability, and corrosion resistance. The adaptability of steel makes it a fundamental material in manufacturing numerous components across different industries.

Titanium is a chemical element with the symbol Ti and atomic number 22. It is a strong, lightweight, and corrosion-resistant metal, known for its high strength-to-weight ratio. Titanium is commonly used in various industries due to its unique combination of properties, making it particularly valuable in applications where a combination of strength, low density, and corrosion resistance is crucial.

In CNC (Computer Numerical Control) machining, titanium is used for a variety of applications. Uses of Titanium in CNC Machining:

- Aerospace Components: Titanium is widely used in the CNC machining of aerospace components, including aircraft structural parts and engine components. Its high strength-to-weight ratio is particularly advantageous in the aerospace industry.

- Medical Devices: Titanium is utilized in CNC machining for medical devices and implants due to its biocompatibility, corrosion resistance, and strength.

- Automotive Components: Titanium is used in CNC machining for certain automotive components, especially in high-performance or racing vehicles, where its lightweight and strong characteristics are beneficial.

- Military and Defense Applications: Titanium is employed in the CNC machining of military and defense components, such as armor, missile components, and specialized equipment.

- Sports Equipment: Titanium is used in CNC machining for sports equipment, including bicycle frames, golf clubs, and tennis racquets, where its lightweight and strong properties are advantageous.

CNC machining of titanium involves using computer-controlled machines to precisely shape and cut the material. Despite the challenges posed by titanium's characteristics, advanced CNC machining techniques, tooling, and cutting strategies have enabled efficient and precise machining of this valuable metal in various industries.

ABS, or Acrylonitrile Butadiene Styrene, is a common thermoplastic polymer known for its durability, impact resistance, and versatility. It belongs to the family of styrene-based plastics and is widely used in manufacturing and various industries due to its favorable mechanical and thermal properties.

Uses of ABS in CNC Machining:

- Prototyping: ABS is commonly used in CNC machining for prototyping applications, as its machinability allows for the creation of detailed prototypes and functional models.

- Consumer Goods: ABS is widely used in CNC machining for manufacturing consumer goods, such as plastic housings for electronic devices, toys, and various household items.

- Automotive Components: ABS is used in CNC machining for producing automotive components, including interior parts, panels, and structural elements.

- Enclosures and Housings: The ease of machining and the durability of ABS make it suitable for CNC machining enclosures and housings for electronic devices, machinery, and appliances.

- Medical Devices: ABS is employed in CNC machining for certain medical device components, particularly in applications where impact resistance and ease of machining are important.

- Point-of-Purchase Displays: ABS is used in CNC machining for creating point-of-purchase displays and signage due to its ability to be molded into various shapes and its visual appeal.

CNC machining of ABS involves using computer-controlled machines to precisely shape and cut the material. The machinability of ABS, along with its desirable properties, makes it a popular choice for various applications in manufacturing, prototyping, and product development. Additionally, ABS can be easily post-processed, allowing for surface finishing techniques such as painting, plating, or printing to enhance the final appearance of CNC-machined parts.

Acetal, also known as polyoxymethylene (POM), is a high-performance thermoplastic with excellent mechanical properties, low friction coefficient, and good dimensional stability. It is widely used in engineering and manufacturing due to its versatility, durability, and machinability. Acetal is available in two main types: homopolymer and copolymer, each with slightly different properties.

Uses of Acetal in CNC Machining:

- Gears and Bearings: Acetal is commonly used in CNC machining for producing gears and bearings due to its low friction coefficient, wear resistance, and high mechanical strength.

- Bushings and Rollers: The machinability and durability of acetal make it suitable for CNC machining bushings and rollers for various applications.

- Automotive Components: Acetal is used in CNC machining for manufacturing automotive components such as connectors, clips, and interior parts.

- Electronic Components: Acetal is employed in CNC machining for producing electronic components, including insulating parts, connectors, and housings.

- Food Processing Equipment: The low moisture absorption and chemical resistance of acetal make it suitable for CNC machining parts for food processing equipment, such as conveyor components.

- Medical Devices: Acetal is used in CNC machining for certain medical device components, benefiting from its biocompatibility, machinability, and resistance to chemicals.

- Consumer Goods: Acetal is utilized in CNC machining for manufacturing consumer goods, including handles, knobs, and various components requiring high mechanical strength and precision.

CNC machining of acetal involves using computer-controlled machines to precisely shape and cut the material. Acetal's combination of properties makes it a preferred choice for applications where mechanical performance, wear resistance, and dimensional stability are critical. The ease of machining further enhances its applicability in the production of intricate components across various industries.

Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic material with optical clarity and excellent weather resistance. It is widely used in various applications due to its versatility, lightweight nature, and ease of fabrication. Acrylic is available in different forms, including sheets, rods, and tubes, making it suitable for a range of CNC (Computer Numerical Control) machining applications.

Uses of Acrylic in CNC Machining:

- Signage and Displays: Acrylic is commonly used in CNC machining for creating signage, displays, and point-of-purchase materials due to its optical clarity and ease of machining.

- Prototyping: Acrylic is often used for CNC machining prototypes, especially in design and engineering applications, where its machinability allows for the creation of detailed models.

- Architectural Elements: Acrylic is used in CNC machining for architectural elements such as decorative panels, lighting fixtures, and transparent barriers.

- Lighting Components: Acrylic is employed in CNC machining for producing lighting components, including diffusers and lenses, due to its optical clarity and ability to transmit light.

- Automotive Components: Acrylic is used for CNC machining certain automotive components, such as light covers and interior parts, where transparency and aesthetics are important.

- Consumer Goods: Acrylic is utilized in CNC machining for manufacturing various consumer goods, including decorative items, holders, and cosmetic displays.

- Medical Devices: Acrylic is used in CNC machining for certain medical device components, taking advantage of its clarity, ease of machining, and biocompatibility.

CNC machining of acrylic involves using computer-controlled machines to precisely cut and shape the material. The ease of machining and the optical properties of acrylic make it a popular choice for applications requiring transparency, precision, and aesthetics across industries such as signage, design, architecture, and consumer goods.

Fiberglass Reinforced Plastics (FRP), also known as glass-reinforced plastics or composite materials, are a type of composite material made by combining a polymer matrix with glass fibers. The polymer matrix, typically a thermosetting resin such as polyester or epoxy, binds the glass fibers together, creating a strong and durable material with a variety of applications. The inclusion of glass fibers enhances the strength, stiffness, and impact resistance of the final composite.

Uses of Fiberglass Reinforced Plastics in CNC Machining:

- Automotive Components: FRP is used in CNC machining for producing automotive components, including body panels, interior parts, and structural components, due to its high strength-to-weight ratio and design flexibility.

- Aerospace Components: FRP is employed in CNC machining for certain aerospace components, where lightweight materials with high strength are crucial for fuel efficiency and performance.

- Marine Applications: FRP is widely used in CNC machining for marine applications, including boat hulls, decks, and structural components, thanks to its corrosion resistance and durability in saltwater environments.

- Construction: FRP is used in CNC machining for construction applications, such as panels, structural elements, and decorative components, taking advantage of its strength, lightweight nature, and resistance to environmental factors.

- Infrastructure: FRP is utilized in CNC machining for infrastructure components such as bridge decks, utility enclosures, and structural supports, benefiting from its corrosion resistance and durability.

- Consumer Goods: FRP is employed in CNC machining for manufacturing consumer goods, such as sporting equipment, recreational vehicles, and various molded products.

- Electrical and Electronics: FRP is used in CNC machining for producing electrical and electronic components, where its electrical insulation properties are essential.

CNC machining of Fiberglass Reinforced Plastics involves using computer-controlled machines to precisely cut and shape the composite material. The versatility, strength, and corrosion resistance of FRP make it suitable for a wide range of applications across different industries, especially where a combination of strength, durability, and design flexibility is required.

Nylon is a generic term for a family of synthetic polymers known as polyamides. It is a thermoplastic material that exhibits excellent mechanical properties, including high strength, toughness, and wear resistance. Nylon is commonly used in various applications due to its versatility, durability, and ease of processing.

Uses of Nylon in CNC Machining:

- Gears and Bearings: Nylon is commonly used in CNC machining for producing gears and bearings due to its low friction coefficient, wear resistance, and strength.

- Bushings and Rollers: The toughness and wear resistance of nylon make it suitable for CNC machining bushings and rollers in various applications.

- Automotive Components: Nylon is employed in CNC machining for manufacturing automotive components such as clips, fasteners, and interior parts due to its toughness and chemical resistance.

- Consumer Goods: Nylon is used in CNC machining for producing various consumer goods, including handles, knobs, and parts for appliances, benefiting from its combination of strength and ease of machining.

- Electrical Components: Nylon is employed in CNC machining for electrical components such as insulators, connectors, and housings due to its electrical insulation properties.

- Textile Industry: Nylon is used in CNC machining for creating components used in the textile industry, such as gears and guides for machinery.

- Medical Devices: Nylon is utilized in CNC machining for certain medical device components, where its toughness, biocompatibility, and ease of machining are important.

CNC machining of nylon involves using computer-controlled machines to precisely cut and shape the material. Nylon's combination of mechanical properties makes it suitable for a wide range of applications across industries, including automotive, consumer goods, textiles, and healthcare. The ease of machining and the ability to produce intricate components contribute to nylon's popularity in CNC machining processes.

Phenolic refers to a group of synthetic thermosetting resins that are created by the reaction of phenol (an aromatic organic compound) with formaldehyde. The resulting phenolic resin is reinforced with various materials, such as paper, fabric, or glass, to enhance its mechanical properties. The resulting composite materials are known as phenolic composites, and they exhibit excellent strength, heat resistance, and chemical resistance.

Uses of Phenolic in CNC Machining:

- Insulators: Phenolic composites are used in CNC machining to produce insulators for electrical applications due to their electrical insulation properties.

- Gears and Bearings: Phenolic materials are employed in CNC machining for producing gears and bearings, where their strength and wear resistance are beneficial.

- Aerospace Components: Phenolic composites find applications in CNC machining for aerospace components, where a combination of strength, heat resistance, and low weight is crucial.

- Industrial Components: Phenolic composites are used to CNC machine various industrial components, such as bushings, washers, and spacers, where mechanical strength and chemical resistance are important.

- Electronics: Phenolic materials are utilized in CNC machining for electronic components, including circuit boards and connectors, benefiting from their electrical insulation properties.

- Tooling and Fixtures: Phenolic composites are used in CNC machining for manufacturing tooling and fixtures due to their high strength and dimensional stability.

- Automotive Components: Phenolic materials find applications in CNC machining for automotive components, such as brake components, where heat resistance and strength are critical.

CNC machining of phenolic involves using computer-controlled machines to precisely cut and shape the material. Phenolic composites are valued for their combination of mechanical properties, heat resistance, and chemical resistance, making them suitable for diverse applications across industries. The specific formulation and reinforcement of the phenolic composite can be tailored to meet the requirements of the intended application, allowing for a range of performance characteristics.

Polyamide-imide (PAI) is a high-performance thermoplastic with exceptional thermal and mechanical properties. It belongs to the family of polyimide polymers and is derived from the condensation reaction of an aromatic diamine and an aromatic dianhydride. PAI is known for its high temperature resistance, excellent mechanical strength, chemical resistance, and dimensional stability.

Uses of Polyamide-Imide (PAI) in CNC Machining:

- Aerospace Components: PAI is used in CNC machining for producing aerospace components, such as seals, bushings, and structural parts, where high temperature resistance and mechanical strength are crucial.

- Automotive Components: PAI finds applications in CNC machining for automotive components, including bushings, bearings, and components in the engine compartment, benefiting from its high temperature performance and durability.

- Electrical and Electronic Components: PAI is utilized in CNC machining for electrical and electronic components, such as insulators, connectors, and parts in electronic devices, due to its electrical insulation properties.

- Oil and Gas Industry Parts: PAI is employed in CNC machining for components in the oil and gas industry, including seals, valves, and pump components, where chemical resistance and high temperature resistance are important.

- Industrial Equipment: PAI is used in CNC machining for various industrial equipment components, such as gears, wear plates, and seals, where a combination of mechanical strength and resistance to harsh conditions is needed.

CNC machining of PAI involves using computer-controlled machines to precisely cut and shape the material. The high-performance characteristics of PAI make it suitable for demanding applications in industries such as aerospace, automotive, electronics, and oil and gas. Its ability to maintain its properties under extreme conditions makes it a preferred choice for components that require durability and reliability in challenging environments.

Polycarbonate is a transparent thermoplastic polymer characterized by its high impact resistance, optical clarity, and excellent mechanical properties. It is derived from bisphenol A (BPA) and phosgene through a polymerization process. Polycarbonate is known for its versatility, making it suitable for a wide range of applications.

Uses of Polycarbonate in CNC Machining:

- Prototyping: Polycarbonate is commonly used in CNC machining for prototyping applications, as its ease of machining allows for the creation of detailed prototypes and functional models.

- Transparent Components: Due to its optical clarity, polycarbonate is used in CNC machining for producing transparent components such as windows, lenses, and covers.

- Electronic Components: Polycarbonate is employed in CNC machining for electronic components, including housings, panels, and enclosures, benefiting from its electrical insulation properties.

- Medical Devices: Polycarbonate is used in CNC machining for certain medical device components, taking advantage of its biocompatibility, transparency, and ease of machining.

- Consumer Goods: Polycarbonate is utilized in CNC machining for manufacturing various consumer goods, including protective covers, panels, and decorative items.

- Automotive Components: Polycarbonate finds applications in CNC machining for automotive components such as headlight covers, interior panels, and protective shields, due to its impact resistance and optical clarity.

- Safety Equipment: Polycarbonate is used in CNC machining for safety equipment such as face shields, goggles, and protective guards, where impact resistance and clarity are essential.

CNC machining of polycarbonate involves using computer-controlled machines to precisely cut and shape the material. Polycarbonate's combination of high impact resistance, optical clarity, and ease of machining makes it a popular choice for a variety of applications across industries, including manufacturing, electronics, automotive, and healthcare.

Polyetheretherketone (PEEK) is a high-performance thermoplastic known for its exceptional mechanical, thermal, and chemical properties. PEEK is part of the polyaryletherketone (PAEK) family and is often used in demanding applications where a combination of high temperature resistance, chemical resistance, and mechanical strength is required.

Uses of PEEK in CNC Machining:

- Aerospace Components: PEEK is used in CNC machining for producing aerospace components, such as structural parts and components in aircraft engines, where high temperature resistance and mechanical strength are crucial.

- Medical Devices: PEEK is employed in CNC machining for certain medical device components, including implants and instruments, benefiting from its biocompatibility and mechanical properties.

- Industrial Components: PEEK is used in CNC machining for various industrial components, such as seals, bearings, and structural parts, where a combination of chemical resistance and mechanical strength is required.

- Automotive Components: PEEK finds applications in CNC machining for automotive components, including seals, gaskets, and wear-resistant parts.

Polyetherimide is another high-performance thermoplastic known for its excellent mechanical and thermal properties. It is part of the polyimide family and is often used in applications requiring a combination of high temperature resistance, dimensional stability, and electrical properties.

Uses of PEI in CNC Machining:

- Electrical and Electronic Components: PEI is commonly used in CNC machining for electrical and electronic components, including connectors, insulators, and housings, due to its electrical insulation properties and thermal resistance.

- Automotive Components: PEI finds applications in CNC machining for automotive components, such as connectors, sensors, and interior parts, where a combination of temperature resistance and mechanical strength is required.

CNC machining of both PEEK and PEI involves using computer-controlled machines to precisely cut and shape the materials. These high-performance thermoplastics are chosen for applications demanding exceptional properties in industries such as aerospace, medical, automotive, and electronics.

Polyethylene is a widely used thermoplastic polymer with a variety of applications due to its versatility, low cost, and ease of processing. It is part of the polyolefin family and is produced in various forms, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE). Polyethylene is known for its chemical resistance, low moisture absorption, and good electrical insulation properties.

Uses of Polyethylene in CNC Machining:

- Prototyping: Polyethylene is commonly used in CNC machining for prototyping applications, as its ease of machining allows for the creation of detailed prototypes and functional models.

- Wear Components: Polyethylene is used in CNC machining for producing wear components, such as bushings and sliders, where low friction and abrasion resistance are important.

- Food and Beverage Industry: Polyethylene is employed in CNC machining for components used in the food and beverage industry, such as conveyor parts and packaging components, due to its chemical resistance and low moisture absorption.

- Medical Components: Polyethylene is used in CNC machining for certain medical components, such as disposable devices and parts where cleanliness and chemical resistance are crucial.

- Consumer Goods: Polyethylene is utilized in CNC machining for manufacturing various consumer goods, including plastic containers, toys, and components for household items.

- Automotive Components: Polyethylene finds applications in CNC machining for automotive components, such as interior parts, seals, and protective covers, benefiting from its low cost and ease of machining.

- Industrial Components: Polyethylene is used in CNC machining for various industrial components, including spacers, washers, and insulating parts, where its chemical resistance and machinability are advantageous.

CNC machining of polyethylene involves using computer-controlled machines to precisely cut and shape the material. Polyethylene's combination of properties, including ease of machining and chemical resistance, makes it suitable for a range of applications in industries such as manufacturing, healthcare, automotive, and consumer goods.

Polyphenylene Sulfide (PPS) is a high-performance thermoplastic polymer known for its excellent chemical resistance, high-temperature stability, and dimensional stability. It belongs to the family of sulfide polymers and is characterized by a backbone of alternating sulfur and phenylene (aromatic) rings. PPS is often reinforced with glass fibers to enhance its mechanical properties.

Uses of Polyphenylene Sulfide (PPS) in CNC Machining:

- Electrical and Electronic Components: PPS is commonly used in CNC machining for electrical and electronic components, including connectors, insulators, and housings, due to its electrical insulation properties and high temperature resistance.

- Aerospace Components: PPS finds applications in CNC machining for aerospace components, such as structural parts, gaskets, and insulating components, where a combination of high temperature resistance and mechanical strength is crucial.

- Automotive Components: PPS is employed in CNC machining for automotive components, including connectors, sensors, and under-the-hood parts, benefiting from its chemical resistance and high temperature stability.

- Industrial Components: PPS is used in CNC machining for various industrial components, such as valves, seals, and bearings, where chemical resistance and dimensional stability are important.

- Medical Devices: PPS is utilized in CNC machining for certain medical device components, taking advantage of its chemical resistance, low moisture absorption, and biocompatibility.

CNC machining of PPS involves using computer-controlled machines to precisely cut and shape the material. PPS's combination of high-temperature resistance, chemical resistance, and mechanical properties makes it suitable for demanding applications in industries such as aerospace, automotive, electronics, healthcare, and industrial manufacturing.

Polypropylene (PP) is a thermoplastic polymer that belongs to the polyolefin family. It is widely used in various applications due to its low cost, lightweight nature, chemical resistance, and versatility. Polypropylene is known for its excellent balance of properties, making it suitable for both industrial and consumer applications.

Uses of Polypropylene in CNC Machining:

- Prototyping: Polypropylene is commonly used in CNC machining for prototyping applications, as its ease of machining allows for the creation of detailed prototypes and functional models.

- Consumer Goods: Polypropylene is widely used in CNC machining for manufacturing various consumer goods, including plastic containers, packaging, toys, and components for household items.

- Automotive Components: Polypropylene finds applications in CNC machining for automotive components, such as interior parts, panels, and protective covers, benefiting from its low cost and ease of machining.

- Industrial Components: Polypropylene is used in CNC machining for various industrial components, including spacers, washers, and insulating parts, where its chemical resistance and machinability are advantageous.

- Medical Components: Polypropylene is used in CNC machining for certain medical device components, such as disposable devices and parts where cleanliness and chemical resistance are crucial.

- Outdoor and Recreational Products: Polypropylene is employed in CNC machining for outdoor and recreational products, including sports equipment, containers, and parts of camping gear, where its lightweight and durable nature are beneficial.

CNC machining of polypropylene involves using computer-controlled machines to precisely cut and shape the material. Polypropylene's combination of properties, including chemical resistance, low cost, and ease of machining, makes it a popular choice for a wide range of applications in industries such as manufacturing, consumer goods, automotive, healthcare, and outdoor recreation.

Polystyrene is a versatile thermoplastic polymer that belongs to the styrenic polymer family. It is commonly used in various applications due to its low cost, ease of processing, and lightweight nature. Polystyrene is available in two main forms: high-impact polystyrene (HIPS) and general-purpose polystyrene (GPPS). It is known for its transparency, rigidity, and excellent electrical insulation properties.

Uses of Polystyrene in CNC Machining:

- Prototyping: Polystyrene, particularly HIPS, is commonly used in CNC machining for prototyping applications. Its ease of machining allows for the creation of detailed prototypes and models.

- Model Making: Polystyrene is used for architectural models, product models, and other types of models due to its ease of machining and affordability.

- Signage and Displays: Polystyrene, especially HIPS, is used in CNC machining for creating signage, displays, and point-of-purchase materials. Its transparency or opacity can be customized for specific design requirements.

- Educational Models: Polystyrene is used in CNC machining for creating educational models and aids, where lightweight and cost-effective materials are preferred.

- Thermoforming: Polystyrene sheets can be machined using CNC processes for thermoforming applications, where the material is heated and shaped to create various products like packaging containers.

CNC machining of polystyrene involves using computer-controlled machines to precisely cut and shape the material. Polystyrene's affordability, ease of machining, and versatility make it suitable for applications in various industries, including manufacturing, education, advertising, and prototyping. However, it's important to note that polystyrene is not suitable for applications requiring high-temperature resistance or structural strength.

Polytetrafluoroethylene (PTFE) is a high-performance synthetic fluoropolymer of tetrafluoroethylene. It is known for its exceptional chemical resistance, low friction coefficient, high temperature resistance, and electrical insulation properties. PTFE is widely recognized by the brand name Teflon®, which is commonly associated with non-stick coatings in cookware. In CNC machining, PTFE is used for various applications due to its unique combination of properties.

Uses of PTFE in CNC Machining:

- Bushings and Bearings: PTFE is commonly used in CNC machining for producing bushings and bearings due to its low friction properties and self-lubricating nature.

- Seals and Gaskets: PTFE is utilized in CNC machining for manufacturing seals and gaskets in various industries, including automotive and aerospace, where chemical resistance and reliability are crucial.

- Valve Components: PTFE is used for CNC machining components of valves and other fluid-handling systems due to its chemical resistance and low friction.

- Insulators: PTFE's excellent electrical insulation properties make it suitable for CNC machining insulators used in electronic and electrical applications.

- Piston Rings: PTFE is used for CNC machining piston rings in certain applications, where its low friction and wear-resistant properties are advantageous.

- Medical Components: PTFE is employed in CNC machining for certain medical device components, taking advantage of its biocompatibility and chemical resistance.

- Slide Plates and Wear Strips: PTFE is used for CNC machining slide plates and wear strips in machinery, where low friction and resistance to wear are essential.

CNC machining of PTFE involves using computer-controlled machines to precisely cut and shape the material. PTFE's unique properties make it a preferred choice for applications where chemical resistance, low friction, and high temperature resistance are critical. It is commonly used in industries such as aerospace, automotive, electronics, healthcare, and manufacturing.

Polyvinyl chloride (PVC) is a versatile thermoplastic polymer derived from vinyl chloride monomers. PVC is one of the most widely used plastics due to its cost-effectiveness, durability, chemical resistance, and ease of processing. It is available in different forms, such as rigid PVC (RPVC) and flexible PVC (FPVC), and is used in various applications across industries.

Uses of PVC in CNC Machining:

- Signage and Displays: Rigid PVC is commonly used in CNC machining for creating signage, displays, and point-of-purchase materials due to its ease of machining and versatility.

- Prototyping: PVC is used in CNC machining for prototyping applications, particularly in product design and development.

- Model Making: PVC is employed for creating architectural models, product models, and other types of models due to its ease of machining and cost-effectiveness.

- Automotive Components: PVC, especially rigid PVC, finds applications in CNC machining for automotive components such as interior parts, panels, and protective covers.

- Industrial Components: PVC is used in CNC machining for various industrial components, including spacers, washers, and insulating parts, where its chemical resistance and machinability are advantageous.

- Construction Materials: PVC is widely used in the construction industry for CNC-machined components such as window frames, pipes, and structural elements due to its durability and weather resistance.

- Consumer Goods: PVC is utilized in CNC machining for manufacturing various consumer goods, including plastic containers, packaging, and components for household items.

CNC machining of PVC involves using computer-controlled machines to precisely cut and shape the material. PVC's combination of properties, including cost-effectiveness, versatility, and ease of machining, makes it suitable for a wide range of applications in industries such as manufacturing, construction, advertising, and consumer goods. It's important to note that certain safety precautions are necessary when machining PVC due to the release of chlorine gas when the material is heated excessively. Proper ventilation and adherence to safety guidelines are crucial in CNC machining PVC.

Polyvinylidene fluoride (PVDF) is a high-performance thermoplastic polymer known for its excellent chemical resistance, mechanical properties, and stability at high temperatures. It belongs to the fluoropolymer family and is known for its durability, weather resistance, and electrical insulation properties. PVDF is often used in demanding applications where a combination of these properties is crucial.

Uses of PVDF in CNC Machining:

- Chemical Processing Equipment: PVDF is commonly used in CNC machining for producing components used in chemical processing equipment, such as valves, fittings, and pumps, where chemical resistance is critical.

- Semiconductor Industry: PVDF is used in CNC machining for manufacturing components for the semiconductor industry, including fittings and connectors, benefiting from its electrical insulation properties.

- Aerospace Components: PVDF finds applications in CNC machining for aerospace components, such as ducting, connectors, and structural parts, where a combination of chemical resistance and mechanical strength is crucial.

- Medical Devices: PVDF is employed in CNC machining for certain medical device components, taking advantage of its biocompatibility and chemical resistance.

- Oil and Gas Industry: PVDF is used for CNC machining components in the oil and gas industry, including seals, valves, and connectors, where resistance to harsh environments is important.

- Electrical Components: PVDF is used in CNC machining for electrical components, such as insulators and connectors, due to its electrical insulation properties.

- Outdoor Applications: PVDF is suitable for CNC machining components used in outdoor applications, such as architectural elements and cladding, where weather resistance is essential.

CNC machining of PVDF involves using computer-controlled machines to precisely cut and shape the material. PVDF's unique combination of properties makes it suitable for applications in industries such as chemical processing, aerospace, electronics, healthcare, and construction. Its ability to maintain performance in challenging environments makes it a preferred choice for critical components in various applications.

"Teflon" is a brand name commonly associated with a specific type of polytetrafluoroethylene (PTFE), a high-performance synthetic fluoropolymer of tetrafluoroethylene. The term "Teflon" is a registered trademark of Chemours, a company that produces a variety of fluoropolymer products. PTFE, including the Teflon brand, is known for its exceptional non-stick properties, chemical resistance, low friction coefficient, and high-temperature stability.

Uses of Teflon in CNC Machining:

- Bushings and Bearings: Teflon is commonly used in CNC machining for producing bushings and bearings due to its low friction properties and self-lubricating nature.

- Seals and Gaskets: Teflon is utilized in CNC machining for manufacturing seals and gaskets in various industries, including automotive and aerospace, where chemical resistance and reliability are crucial.

- Valve Components: Teflon is used for CNC machining components of valves and other fluid-handling systems due to its chemical resistance and low friction.

- Insulators: Teflon's excellent electrical insulation properties make it suitable for CNC machining insulators used in electronic and electrical applications.

- Piston Rings: Teflon is used for CNC machining piston rings in certain applications, where its low friction and wear-resistant properties are advantageous.

- Medical Components: Teflon is employed in CNC machining for certain medical device components, taking advantage of its biocompatibility and chemical resistance.

- Slide Plates and Wear Strips: Teflon is used for CNC machining slide plates and wear strips in machinery, where low friction and resistance to wear are essential.

CNC machining of Teflon involves using computer-controlled machines to precisely cut and shape the material. Teflon's unique properties make it a preferred choice for applications where non-stick, chemical resistance, and low friction are critical. It is commonly used in industries such as aerospace, automotive, electronics, healthcare, and manufacturing.

Custom Machined Parts

By seamlessly integrating advanced CNC machining technologies, The Hinz Company positions itself at the forefront precision engineering of custom machines parts. Their dedication to innovation is reflected in their state-of-the-art manufacturing processes, which enable the production of intricate custom machined parts with exceptional accuracy and efficiency. The company's responsive service is a cornerstone of their operations, ensuring that clients' unique specifications and requirements are not only met but exceeded. This commitment to tailored solutions has solidified enduring relationships with clients, as The Hinz Company becomes a trusted partner in the realization of superior products. Moreover, their competitive cost structure underscores their commitment to delivering value, making them an industry leader in the realm of custom machined parts.

Looking for High Volume Swiss CNC Parts?

Hinz Company specializes in the production of high-volume Swiss CNC machined parts, leveraging advanced Swiss machining technology for precision manufacturing. Their expertise caters to diverse industries, including medical, electronics, aerospace, automotive, and watchmaking. Hinz Company excels in crafting intricate components like surgical instruments, electronic connectors, aerospace hardware, automotive parts, and precision watch components. With a focus on efficiency, their employment of simultaneous machining on CNC lathes ensures faster production times, meeting the demands of mass production. Hinz Company's commitment to versatility is evident in their ability to work with various materials, underscoring their flexibility in addressing specific manufacturing needs and consistently delivering high-precision CNC parts.

Responsive Machining

The Hinz Company places a strong emphasis on its distinctive "Responsive Machining" consultation process, a cornerstone of its commitment to delivering exceptional precision and accuracy in every project. At the core of this approach is the thorough examination of prints submitted by clients. The company's dedication to responsiveness ensures that each project undergoes a meticulous review, guaranteeing that all specifications are thoroughly understood and incorporated into the machining process.

This commitment to a "Responsive Machining" philosophy is designed to benefit clients by not only meeting but exceeding their expectations. The iterative nature of the consultation process allows for adjustments and refinements to be made as many times as necessary, ensuring that the final product aligns precisely with the client's specifications. This iterative refinement not only enhances the accuracy of the machined parts but also contributes to substantial cost savings on a per-part basis.

By actively engaging with clients throughout the machining consultation process, The Hinz Company establishes a collaborative environment where feedback is welcomed, and adjustments are seamlessly integrated. This approach not only streamlines the production process but also minimizes the likelihood of errors or misunderstandings, ultimately contributing to a more efficient and cost-effective outcome.

In essence, The Hinz Company's commitment to "Responsive Machining" goes beyond the conventional service model. It reflects a dedication to client satisfaction, cost-effectiveness, and a relentless pursuit of precision in every aspect of the machining process. Clients can trust that their projects are in capable hands, where the combination of expertise, responsiveness, and attention to detail results in the delivery of high-quality, accurate machined parts.

What is CNC Multi-Axis Swiss Turning?

CNC Multi-Axis Swiss Turning, also known as Swiss-type CNC turning or simply Swiss turning, is a specialized machining process used for precision manufacturing of small, complex, and high-precision components, particularly in the aerospace, medical, automotive, and electronics industries. This machining technique is ideal for creating intricate parts with tight tolerances and fine surface finishes.

Here's a breakdown of the key components and characteristics of CNC Multi-Axis Swiss Turning:

-

Swiss-Type Lathe: The foundation of Swiss turning is a CNC lathe machine, often referred to as a Swiss-type lathe or Swiss screw machine. This type of lathe features a sliding headstock that holds the workpiece, a guide bushing to support and stabilize the material being machined, and a gang tooling setup. Unlike traditional lathes, Swiss lathes have a unique design that allows for precise and simultaneous machining of multiple features along the length of the workpiece.

-

Multi-Axis Capability: CNC Multi-Axis Swiss Turning machines are equipped with multiple axes of motion, typically including X, Y, Z, and often additional rotary axes (C and B axes). This multi-axis capability enables the simultaneous machining of various features, including turning, milling, drilling, and cross-drilling, on different parts of the workpiece without the need for multiple setups.

-

Guide Bushing: The guide bushing is a critical component in Swiss turning. It provides support and stability to the workpiece, especially when machining long and slender parts. The guide bushing is located close to the cutting tools, reducing vibration and ensuring excellent precision.

-

Sliding Headstock: The sliding headstock of a Swiss-type lathe holds the workpiece and allows it to move axially while rotating. This design eliminates the need for a traditional tailstock, making it suitable for machining long and slender parts.

-

Small Diameter Workpieces: Swiss turning is particularly well-suited for machining small-diameter materials, often in the range of 0.5 mm to 32 mm (0.02 inches to 1.25 inches) or even smaller. This precision machining process is commonly used for producing components such as medical implants, watch parts, aerospace fasteners, and electronic connectors.

-

High Precision: Swiss turning is renowned for its exceptional precision and repeatability. The combination of tight tolerances, multi-axis machining, and the use of guide bushings ensures that the finished components meet strict quality requirements.

-

Efficient Chip Management: Swiss lathes are designed with effective chip management systems to ensure efficient removal of metal chips produced during the machining process. This helps maintain the quality of the finished parts.

In summary, CNC Multi-Axis Swiss Turning is a specialized machining process that excels in producing small, complex, and high-precision components with tight tolerances. Its unique design and multi-axis capabilities make it a preferred choice for industries that demand precision and efficiency in the production of intricate parts.