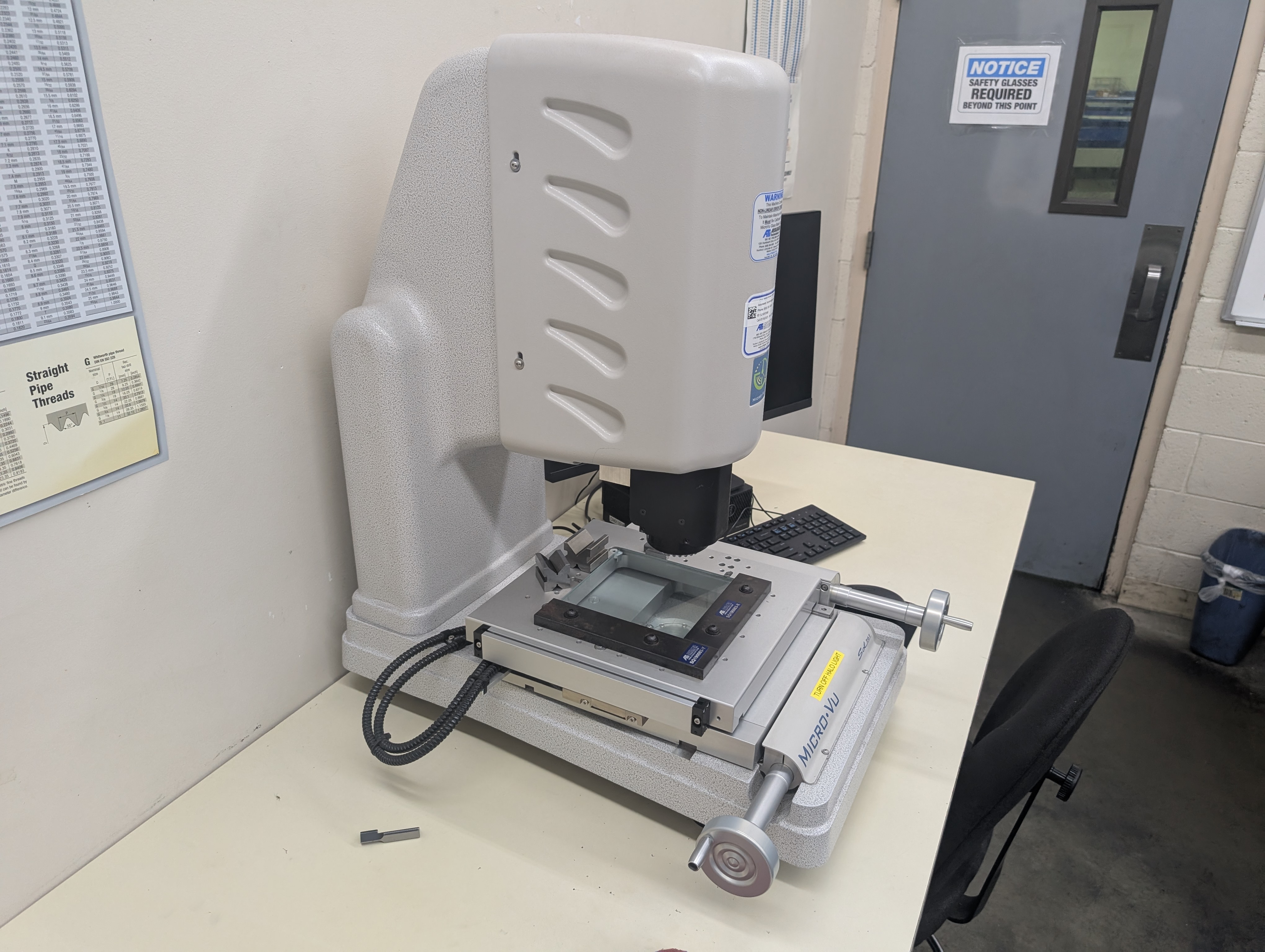

Micro-Vu Sol 16

Hinz Company is proud to announce the addition of a Micro-Vu Sol 16 to our lineup of advanced inspection equipment. This state-of-the-art vision measuring system represents a significant investment in our commitment to delivering the highest quality Swiss-machined components to our customers.

With the Micro-Vu Sol 16, we can perform faster, more precise, and fully automated measurements, ensuring every part we produce meets exact specifications. This machine enhances our ability to verify complex geometries, fine details, and tight tolerances — giving our customers even greater confidence in the accuracy and reliability of our work.

This new capability not only strengthens our quality control processes but also supports our ongoing mission to provide world-class machining solutions to industries where precision is critical, such as medical devices, aerospace, defense, and electronics.

The Micro-Vu Sol 16 combines advanced optics, intelligent lighting, and precision calibration to deliver repeatable, micron-level measurements. It is designed to handle a wide range of part sizes and materials, making it an incredibly versatile tool for our inspection team.

Key Capabilities

- High-Resolution Zoom – 6.5× optical zoom with an additional 3× digital zoom for detailed inspection without changing lenses.

- Advanced Edge Detection – Provides accurate, repeatable measurements by automatically identifying part features and boundaries.

- Programmable Lighting – Multiple lighting modes, including ring, surface, profile, and axial lighting, allow for optimal visibility of complex geometries.

- Automated Calibration & Compensation – Ensures accuracy across the entire measurement range with non-linear stage and optics compensation.

- Fast, Automated Measurement Routines – Reduces inspection time while improving throughput and consistency.

Technical Specifications

- XYZ Measurement Volume 160 × 160 × 160 mm (Sol-165) or 315 × 315 × 160/250 mm (Sol-341/342)

- Accuracy 3.6 + L/190 or 3.9 + L/180 µm (depending on model)

- Resolution 1 µm

- Max Stage Load 7.5 – 11 kg evenly distributed

- Footprint Compact design, ranging from 630 × 732 × 773 mm to 939 × 1114 × 1015 mm

- Operating Environment 18-27 °C with stable conditions; 30-80% humidity (non-condensing)

- Power 100-240 VAC, max draw 120 W

Applications at Hinz

The Micro-Vu Sol 16 will play a crucial role in quality assurance and process validation. Its capabilities are ideal for:

- Swiss CNC-machined components requiring precise dimensional verification.

- Medical device parts, where accuracy and reliability are paramount.

- Aerospace and defense components with tight tolerances and complex geometries.

- High-volume production runs, where automated routines improve speed and consistency.

By incorporating this cutting-edge inspection system, Hinz Company continues to raise the bar in delivering high-precision, defect-free components for our customers across demanding industries.

Includes Feeler FTS-27 Turret lathe (1-1/16” bar capacity), Mitek Manual surface grinder, Bridgeport vertical mill (12” by 36” table), Coining press, Staking press, drill presses, horizontal production saw, vibratory deburring bowl.

Includes Brown & Sharp CMM (PC-DMIS), (2) programmable video comparators, multiple optical comparators, Mitutoyo profilometers, Defelsko coating thickness meters, thread ring and plug gauging, O.D. micrometers to 6.000”, calipers to 40.000”, Sunnen bore gauges (up to 2.900 I.D.), digital height stands etc. All inspection equipment is calibrated to be traceable to the National Bureau of Standards under MIL-STD-45662.