| Industry Focus |

Aerospace Machine Tool |

| Intended Applications |

Machine components Pins |

| Tolerances |

Straightness: ± 0.0005 Concentricity: ± 0.0005 |

| Part Diameter |

Min Max |

| Part Length |

Min Max |

| Machining Processes | Internal Forming Parting/Cutting Facing Turning:

Knurling |

| Equipment | Lathe

|

| Fixturing |

Three-jaw chuck In-House Fixturing & Tooling |

| Equipment Capabilities |

CNC Control Capabilities CAD Design Services |

| Machinery Axis |

8 Axis Live Tooling |

| Secondary Services Offered |

Assembly Milling |

| Industry Focus |

Aerospace Industrial |

| Advantages of Turning |

Tight tolerances Materials compatible |

| Production Volume |

1 min Small Run |

| Lead Times Available |

Quoted on job by job basis Rush Services Available |

| Industry Standards |

International Organization for Standardization ISO -9001 |

| Efficiency |

Six Sigma Compliant Lights Out Manufacturing |

| File Formats | AutoCAD (DWG,DWZ) |

Materials

Metals: Alloy Steels, Aluminum, Beryllium, Brass, Bronze Alloys, Carbon Steel, Copper, Molybdenum, Nickel, Palladium, Stainless, Steel, Titanium.

Materials (Plastic Polymers): ABS (Acrylonitrile Butadiene Styrene), Acetal, Acrylic, Fiberglass Reinforced Plastics, Nylon, Phenolic, Polyamide-Imide, Polycarbonate, Polyetheretherketone (PEEK)Polyetherimide, Polyethylene, Polyphenylene Sulfide, Polypropylene, Polystyrene, PTFE (PolyTetraFluoroEthylene), PVC (Polyvinyl Chloride), PVDF (Polyvinylidene Fluoride),Teflon ®.

The Hinz Company prides itself with a "Responsive Machining" consultation process in regards to prints submitted. This insures precise accuracy as many times as needed, saving the client money on a per-part basis.

-

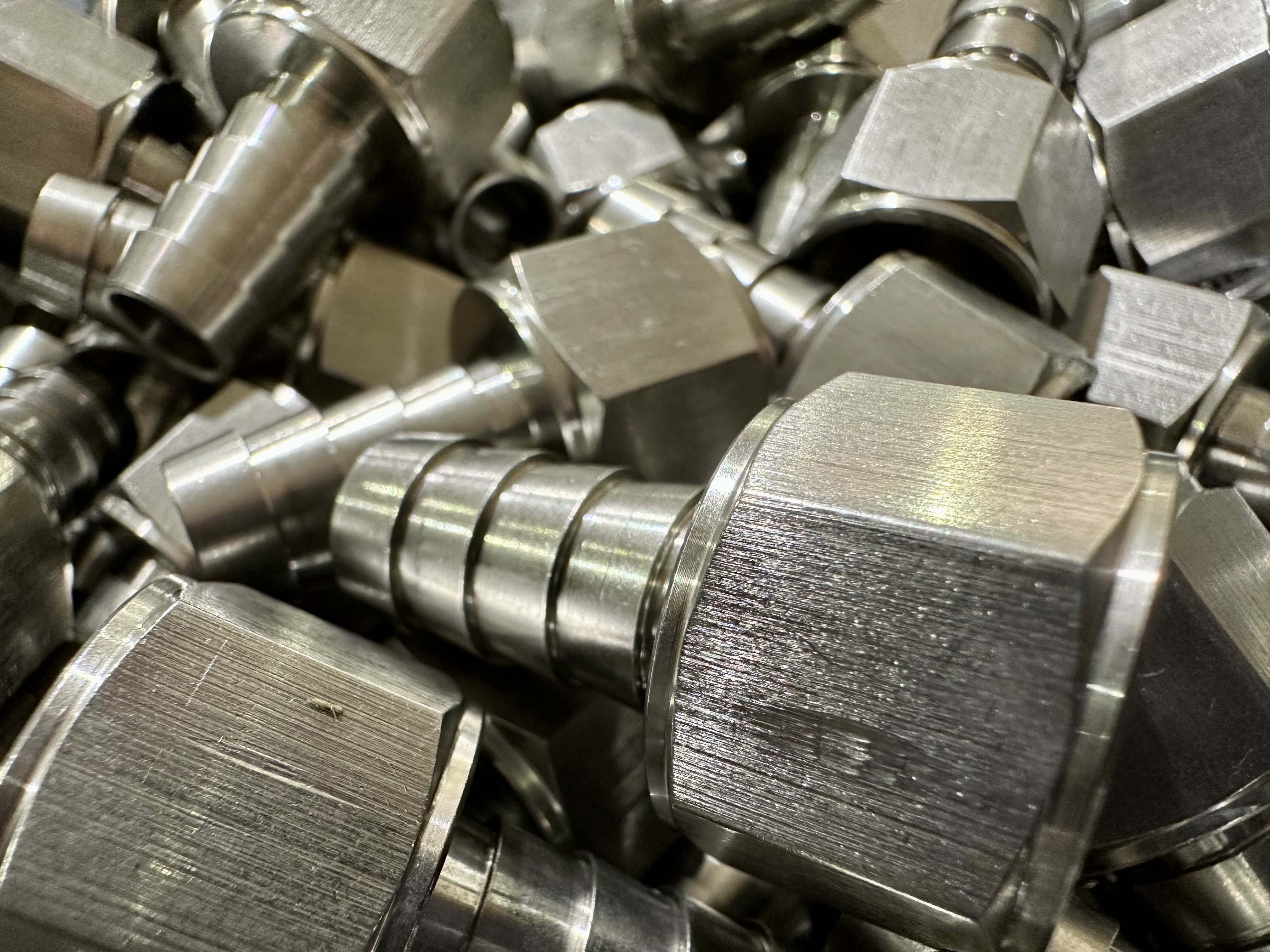

CNC Multi-Axis Turning of a Stainless Steel Hold-Down Knob for the Aerospace Industry

Contracted by an aerospace industry leader, The Hinz Company constructed a multi-axis turned hold-down knob used for commerical airline applications. Produced from s...

-

CNC Multi-Axis turning Conveyor shaft (Knurled / Smooth)

Looking out the window, an Amazon truck whizzes by. Ever wonder how all those packages got into the truck? It is almost unfathomable to imagine such a process considering the global volume of shipm...

-

Custom CNC Multi-Axis Machining of Piston

When Oshkosh Truck was awarded the Joint Light Tactical Vehicle (JLTV) program, we knew things were going to change at Hinz. Prototypes had been produced, small production runs ensu...

-

CNC Multi-Axis Machining of Steel Tube for Hydraulic Industry

Contracted by a hydraulic industry leader, The Hinz Company constructed a multi-axis turned steel tube used for commerical hydraulic applications. Produced from stee...

Whether you need precise components for aircraft engines, avionics systems, or other critical aerospace applications, The Hinz Company is your trusted source. Our commitment to excellence in CNC Multi Axis Swiss Turning services, combined with our industry-specific knowledge, positions us as a reliable partner for all your aerospace machining needs. Experience the precision and quality that set us apart in the Aerospace industry with The Hinz Company.

When you require precise components for agricultural machinery, irrigation systems, or other critical applications in the agriculture industry, The Hinz Company is your trusted source. Our dedication to excellence in CNC Multi Axis Swiss Turning services, coupled with our industry-specific expertise, makes us a reliable partner for all your agricultural machining requirements. Discover the accuracy and quality that distinguish us in the Agriculture sector with The Hinz Company.

When it comes to precise components for automotive engines, electronic systems, or other critical automotive applications, look no further than The Hinz Company. We excel in CNC Multi Axis Swiss Turning services and possess specialized knowledge of the automotive industry, making us the dependable partner you need for all your machining requirements. Discover unparalleled precision and quality that sets us apart in the Automotive sector with The Hinz Company.

When it comes to precise components for hydraulic systems, whether it's for aircraft engines, avionics, or other critical applications, The Hinz Company is your trusted source. Our dedication to excellence in CNC Multi Axis Swiss Turning services, along with our specialized knowledge in hydraulics, makes us the reliable partner you need for all your hydraulic machining needs. Experience the unmatched precision and quality that sets us apart in the Hydraulic industry with The Hinz Company.

When it comes to precise components for medical equipment, medical devices, or other critical medical applications, The Hinz Company is your trusted source. Our dedication to excellence in CNC Multi Axis Swiss Turning services, along with our industry-specific knowledge in the medical field, makes us a reliable partner for all your medical machining needs. Experience the precision and quality that set us apart in the Medical industry with The Hinz Company.

Custom Machined Parts

By seamlessly integrating advanced CNC machining technologies, The Hinz Company positions itself at the forefront precision engineering of custom machines parts. Their dedication to innovation is reflected in their state-of-the-art manufacturing processes, which enable the production of intricate custom machined parts with exceptional accuracy and efficiency. The company's responsive service is a cornerstone of their operations, ensuring that clients' unique specifications and requirements are not only met but exceeded. This commitment to tailored solutions has solidified enduring relationships with clients, as The Hinz Company becomes a trusted partner in the realization of superior products. Moreover, their competitive cost structure underscores their commitment to delivering value, making them an industry leader in the realm of custom machined parts.

Looking for High Volume Swiss CNC Parts?

Hinz Company specializes in the production of high-volume Swiss CNC machined parts, leveraging advanced Swiss machining technology for precision manufacturing. Their expertise caters to diverse industries, including medical, electronics, aerospace, automotive, and watchmaking. Hinz Company excels in crafting intricate components like surgical instruments, electronic connectors, aerospace hardware, automotive parts, and precision watch components. With a focus on efficiency, their employment of simultaneous machining on CNC lathes ensures faster production times, meeting the demands of mass production. Hinz Company's commitment to versatility is evident in their ability to work with various materials, underscoring their flexibility in addressing specific manufacturing needs and consistently delivering high-precision CNC parts.

Responsive Machining

The Hinz Company places a strong emphasis on its distinctive "Responsive Machining" consultation process, a cornerstone of its commitment to delivering exceptional precision and accuracy in every project. At the core of this approach is the thorough examination of prints submitted by clients. The company's dedication to responsiveness ensures that each project undergoes a meticulous review, guaranteeing that all specifications are thoroughly understood and incorporated into the machining process.

This commitment to a "Responsive Machining" philosophy is designed to benefit clients by not only meeting but exceeding their expectations. The iterative nature of the consultation process allows for adjustments and refinements to be made as many times as necessary, ensuring that the final product aligns precisely with the client's specifications. This iterative refinement not only enhances the accuracy of the machined parts but also contributes to substantial cost savings on a per-part basis.

By actively engaging with clients throughout the machining consultation process, The Hinz Company establishes a collaborative environment where feedback is welcomed, and adjustments are seamlessly integrated. This approach not only streamlines the production process but also minimizes the likelihood of errors or misunderstandings, ultimately contributing to a more efficient and cost-effective outcome.

In essence, The Hinz Company's commitment to "Responsive Machining" goes beyond the conventional service model. It reflects a dedication to client satisfaction, cost-effectiveness, and a relentless pursuit of precision in every aspect of the machining process. Clients can trust that their projects are in capable hands, where the combination of expertise, responsiveness, and attention to detail results in the delivery of high-quality, accurate machined parts.

What is CNC Multi-Axis Turning?

CNC Multi-Axis Turning, often simply referred to as multi-axis turning or CNC turning, is a machining process used to create cylindrical parts or components from a workpiece by removing material through rotational cutting. This process involves the use of a computer numerical control (CNC) machine, which is capable of precise and automated control of various axes of motion.

Here's a breakdown of the key elements and characteristics of CNC Multi-Axis Turning:

-

CNC Lathe Machine: At the heart of multi-axis turning is a CNC lathe machine. A CNC lathe is designed to hold and rotate the workpiece while various cutting tools are used to shape and machine it. The machine's movements are controlled by a computer program, allowing for precise control over tool positioning and cutting operations.

-

Multiple Axes of Motion: Multi-axis turning machines have several axes of motion. The primary axes include:

- X-Axis: Horizontal movement of the cutting tool along the workpiece's length.

- Z-Axis: Axial movement of the workpiece (in and out of the spindle).

- C-Axis: Rotational movement of the spindle and workpiece, which allows for indexing and contouring operations.

- Additional Axes: Some advanced CNC lathes may have more axes, such as Y-axis for off-center milling or B-axis for angular positioning of the tool.

-

Versatile Machining: Multi-axis turning is versatile and can perform various machining operations, including:

- Turning: Rotating the workpiece while the cutting tool removes material to create cylindrical shapes.

- Facing: Removing material from the end of the workpiece to create flat surfaces.

- Drilling: Creating holes or bores in the workpiece.

- Boring: Enlarging existing holes with precision.

- Threading: Cutting threads on the workpiece's exterior or interior.

-

Complex Geometry: Multi-axis turning is capable of creating parts with intricate and complex geometries. It can produce features like tapers, contours, grooves, and undercuts with high precision.

-

High Precision: CNC Multi-Axis Turning machines are known for their high precision and repeatability. They can achieve tight tolerances and excellent surface finishes, making them suitable for parts that require accuracy.

-

Automation and Efficiency: CNC control allows for automation of the machining process, which reduces manual labor and increases efficiency. Operators program the machine with specific tool paths, and the CNC system executes these instructions consistently.

-

Wide Range of Materials: Multi-axis turning can be used with various materials, including metals (e.g., steel, aluminum, brass), plastics, and even certain composites.

In summary, CNC Multi-Axis Turning is a versatile machining process that uses a CNC lathe with multiple axes of motion to produce cylindrical parts with precision and efficiency. It is widely used in manufacturing industries to create a wide range of components, from simple shafts to complex aerospace and medical parts.